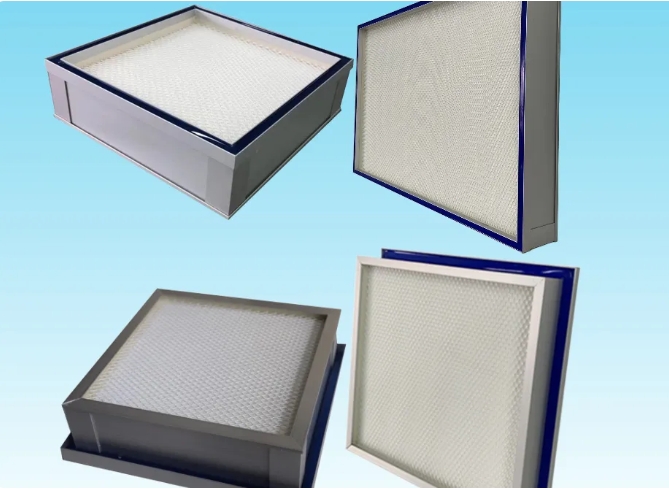

High-efficiency mini-pleated filter

HEPA filter is an important part of modern air purification technology.

High-efficiency mini-pleated filter (HEPA mini-pleated) is a device capable of efficiently filtering tiny particles in the air, and its uniqueness lies in the abandonment of the traditional partition separation method. Structurally, HEPA filter adopts hot sol or other special materials to fix the filter material directly to form a continuous filtration layer.

The working principle of high-efficiency mini-pleatedfilter mainly includes the following: Inertial diffusion and interception principle: Dust particles in the air carry out inertial movement or irregular movement along with the airflow, and when the dust particles hit other objects, they will stick to them. In the filter, the dust particles have a greater chance of collision, the small dust condenses into large dust, and the large dust sinks due to its large weight, thus purifying the air.

Electrostatic effect: The electrostatic force in the filter can make the dust change the trajectory and hit the obstacles, and the electrostatic force can make the dust stick more firmly on the media. This electrostatic effect can significantly improve the filtration effect.

Chemical filtration: There is activated carbon material inside the high-efficiency non-septum filter, and this material has a large adsorption area and strong adsorption force, which can further remove harmful substances in the air.

High-efficiency non-septum filter has the following significant performance characteristics: high filtration efficiency: it can filter out dust particles above 0.12 microns, and the filtration efficiency can reach 13 to 96%.

Good airflow uniformity: Due to the use of special hot melt adhesive divider, it ensures optimal airflow through the filter, so that the air can enjoy smoother and more efficient purification when it passes through the filter.

Low resistance: the partitionless design simplifies the production process and reduces the resistance of the filter, allowing the air to remain more natural and comfortable during the purification process.

Long service life: Due to the use of high-quality filter material and special adhesive sealing technology, side leakage and damage are effectively prevented, extending the service life of the filter.

High-efficiency mini-pleated filters are widely used in occasions with high requirements for cleanliness, such as hospitals, electronics, food, precision machinery, semiconductors, clean rooms and so on. In these occasions, high-efficiency partitionless filters can effectively remove tiny particles and harmful substances in the air to ensure the quality and cleanliness of the air.

Maintenance: HEPA filters need to be inspected and maintained regularly to ensure their normal operation and filtration effect. In the inspection process, attention needs to be paid to parameters such as the sealing of the filter, the integrity of the filter material and the resistance of the filter.

Replacement: When the filter reaches a certain resistance value (final resistance value), it is necessary to replace the filter. The final resistance value is usually set at 2-4 times the initial resistance value. When replacing the filter, it is necessary to follow the correct steps to ensure that the new filter is properly installed and sealed.

To sum up, the high-efficiency mini-pleated filter is a highly efficient, reliable and applicable air purification device for a variety of occasions. Knowledge of its definition, structure, working principle, performance characteristics and application scenarios will help to better use and maintain this filter.

Contact Us

Email: commercial-03@jcanx.com

WhatsApp & Tel: +86 15338430350

+86 15338712916

Address: No. 20 Building, Jihua Street, Longgang District, Shenzhen, China