Bag Filter Customization

Bag Filter is a highly efficient way to remove dust from flue gas. After the bag filter is made of different varieties of fiber filter media, the dusty gas is purified by the initial dust layer formed on the surface of the bag filter, for almost all kinds of dust in general industry, can play a good role in filtering and intercepting, and its dust capture efficiency can reach more than 99% of the dust content of the flue gas. If the filter material used is appropriate, the quality of the bag is reliable, and when the design, manufacture and operation of the dust collector is appropriate, the dust capture efficiency can be as high as 99.9% or more.

We mainly have options in polyester fiber, PPS fiber, PTFE fiber, aramid fiber, acrylic fiber, Japan Toray fiber, etc. as raw materials, there are anti-static, double flame retardant laminating process, the service life is generally 1-4 years, good permeability, high dust collection rate, easy to clear dust, dust removal efficiency up to 98.99%. High filtration precision, high temperature and corrosion resistance.

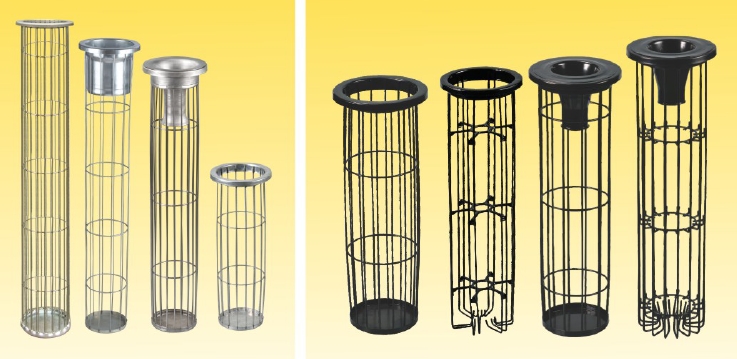

Together with the bag filter, we can also provide cage skeleton for customers' installation convenience.

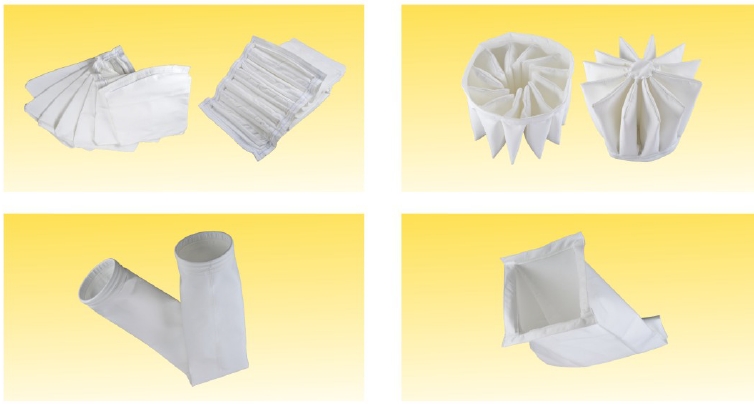

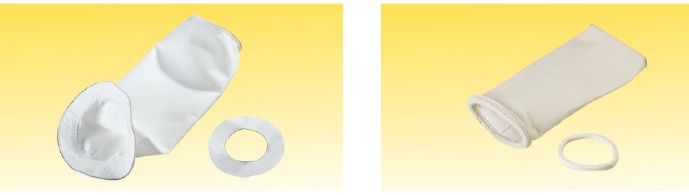

Usually the bag is made into a cylindrical shape, in order to make the structure compact, the bag is also made into a flat bag form. The air volume of the dust collector can range from several hundred cubic meters to one million cubic meters per hour. Due to the different bag forms, combinations and ash removal methods, there are many types of baghouse dust collectors.

As a kind of high-efficiency dust removal equipment, bag filter is widely used in various industrial waste gas, such as light industry, mechanical processing, building materials, chemical industry, non-ferrous metal smelting and iron and steel enterprises, refractory factory, cement factory, ceramic factory, asphalt concrete mixing, garbage incineration, coal-fired boilers, furniture factories, food processing, flour mills, and electronics industry, and so on.